- Heavy duty fabric conveyor belt

- Steel cord conveyor belt

- Chevron conveyor belt

- Sidewall conveyor belt

- Endless conveyor belt

- Special conveyor belt

- OTR Tyre

- Truck and Bus Tyre

- Agricultural Tyre

- Industrial Tyre

Latest news

- The Best Led Street Light Manufacturer

- What is the Price of Led street light?

- Direction of the cause and solution fo

- ACE RUBBER TRUCK TIRES – Superior qual

Contact us

- ADD: Qingzhou high tech industrial park, Shandong, china

- E-mail: info@ace-rubber.com

Cross Rigid conveyor belt

- Product description: It is based in the following main components: (1) Cross-stabilized Base Belts (2) Sidewalls (3) Cleats

Product introduction

Description

It is based in the following main components:

(1) Cross-stabilized Base Belts

(2) Sidewalls

(3) Cleats

Sidewall Conveyor belt has been designed with two corrugated sidewalls and cleats molded to cross-rigid base belt can carry heavy product loads up to the inclined angle of 75°. This belt is popular where space is at a premium and steep incline angles are desired.

The Base Belt:

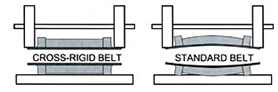

The base belt is designed to bend efficiently in a longitudinal direction and has greater rigidity in a transverse direction by utilizing reinforced fabrics with monofilament, creating a fabric carcass of high tension.

Cross Rigid Conveyor Belt can be deflected from the horizontal to an incline or vertical and back again without bowing or sagging. These deflection points as well as the belt returning on free lateral space by snub idlers definitely require the cross-rigidity of the base belt. The designed mono-filament fabrics provide better returnside support, no wear and tear of cleat and cover rubber is available with various compounds like abrasion resistance oil, heat, and flame resistance.

Specification :

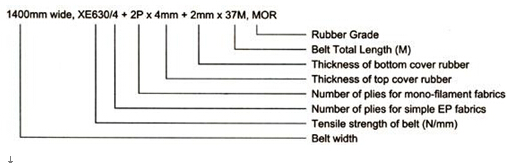

AN EXAMPLE OF BASE BELT INDICATION:

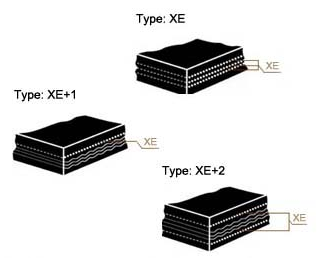

BASE BELT TYPE:

BELT COMPOSITION:

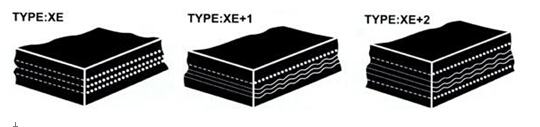

X=Cross-Stabilized

Construction

E=Polyester Tension Plies

+1=One Ply of Cross-Stabilized

+2=Number of Separate Cross-Stabilizing Plies

CONSTRUCTION:

XE+2:

is a mulitiply construction with cut edges

based upon carcass of EP fabric and one

monofilament ply on each side of the EP carcass

integrated into the upper and lower cover.

rubberace

rubberace